VibroMap

FULL-FIELD VIBROMETER

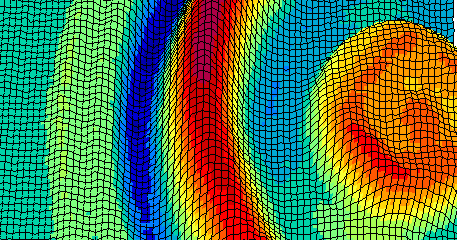

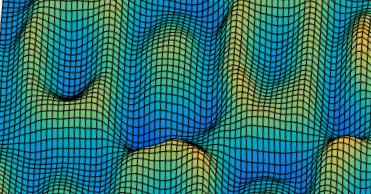

The Optonor VibroMap is a full-field area vibrometer based on TV-holography/ESPI technology. This robust and user-friendly instrument can be used on structures ranging from 1 cm2 to 4 m2. It measures both dynamic and static deflections across the full imaged area. Results are presented using both real-time analogue algorithms as well as numerical algorithms, giving complete vibration amplitude and phase maps or static deflection maps.

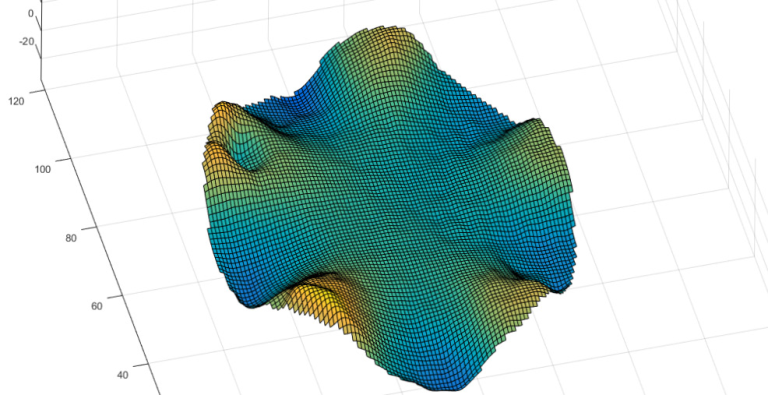

Vibrations and deflections are displayed as animated surface plots or line plots. The VibroMap is a compact and portable instrument with a simple user interface. Turn the key and start your measurements.

- Vibration analysis

- Modal analysis

- Static deflection analysis

- Non-destructive Testing

- Research and Education

- Product and material development

- Quality control and product testing

- Aerospace

- Ship and maritime

- Automotive\

- Oil & Gas/Energy

HIGH FUNCTIONALITY AND ACCURACY

The Optonor VibroMap system utilizes a laser based interferometric technique in which the object is illuminated by an expanded laser beam and imaged by a built-in camera system. When the object vibrates, the laser light reflected by the object surface also “vibrates”. This is detected by the VibroMap by use of an internal reference laser beam that interferes with the reflected object light. The signals are processed by the system computer and presented either as real-time amplitude maps, or by amplitude and phase saved as numerical data.

NUMERICAL ANALYSIS

The numerical mode of operation provides full-field numerical data of vibration amplitude and phase, as well as static displacements. For vibration measurements, the numerical recording with HD resolution is completed in a few seconds. For static displacement measurements, the numerical mode of operation measures the surface displacement between time t and time (t+Δt), where Δt can be sub-second or up to several minutes. The static displacements can also be monitored and measured continuously over a period of time if the object is moved with limited velocity during the recording period.

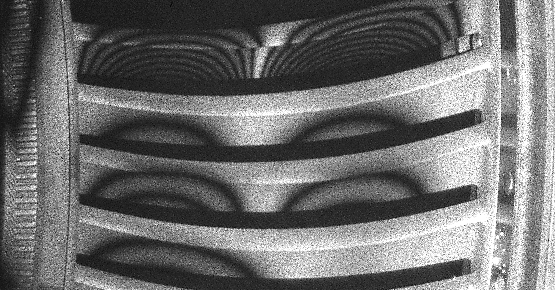

MODAL ANALYSIS – FREQUENCY SCAN

The object vibrations are normally controlled by the VibroMap using the built in signal generator and a vibration excitation unit such as a piezo-element or shaker. Vibration modes with amplitude and phase maps can be measured for all frequencies from DC to 25 MHz. With the frequency scan function, object frequency spectra and response modes may be produced. Frequency modes can be compared to simulation results, and then used in further investigations such as resonance mode Q-factors or non-destructive testing.

DEFECT DETECTION

For simpler and faster interpretation and evaluation, Optonor has developed a Defect Detection Scan routine. By using frequency scanning and advanced filtering routines, the VibroMap system removes global vibration patterns and displays vibration discontinuities and defects only. Interpretation of complex vibration patterns is not necessary when using this functionality.

SPECKLE AVERAGING

When laser light is reflected from rough surfaces, interference effects give speckle noise. The VibroMap system has a speckle averaging module to reduce such speckle noise from measurements, giving high quality vibration maps with high spatial and signal resolution.

RELIABLE TECHNOLOGY

Optonor AS has delivered full field laser systems for more than 20 years. The systems are based on a modern interferometric technology used in a large range of applications within the aerospace, automotive, audio and electronic industries. Many research and educational environments and organizations have also taken advantage of Optonor technologies.

FULL-FIELD OPERATION AND RESULTS

The VibroMap measures the vibrations and static deflections over the entire area that is illuminated by the expanded laser beam. No scanning functionality is required, and no data-point configuration. The operator can also zoom in to examine specific points of interest, or zoom out to analyse larger areas.

ROBUST AND EFFICIENT

The robust and efficient algorithms for data filtering and data analysis enable this high sensitivity technology to be applied in many applications. The software generates output data and results in various exportable formats, so that 3rd party software can be used in further analysis. The robust software and hardware makes the VibroMap system operable by a wide range of users.

REAL TIME ANALYSIS

The Vibromap system provides two basic modes of operation for both static and dynamic measurements. In the real-time mode of operation, the full field measurements are continuously updated at the camera frame rate, and the displacement map is presented as iso-displacement contours. Any change in displacement in response to changes in either the excitation frequency, the boundary conditions or the applied loading is immediately displayed by the system.

USER FRIENDLY OPERATION

The VibroMap is a turn-key instrument where the operator or technician can perform advanced testing within short time. Training and familiarization is provided by Optonor as required. The operator can easily make recordings for documentation and analysis. The multi-mode technology provides very high confidence in the measurement setup and the quality of the results.

FEATURES & BENEFITS

- Full-field measurement with real-time analysis

- Amplitude, phase and deflection maps

- Flexible object excitation solutions:

- User controlled vibrations

- Thermal deflection

- Pressure/vacuum response

- Animated displays and data-export solutions

- User friendly and robust

- Fast and cost-effective data processing

“The multi-mode technology provides very high confidence in the measurement setup and the quality of the result”