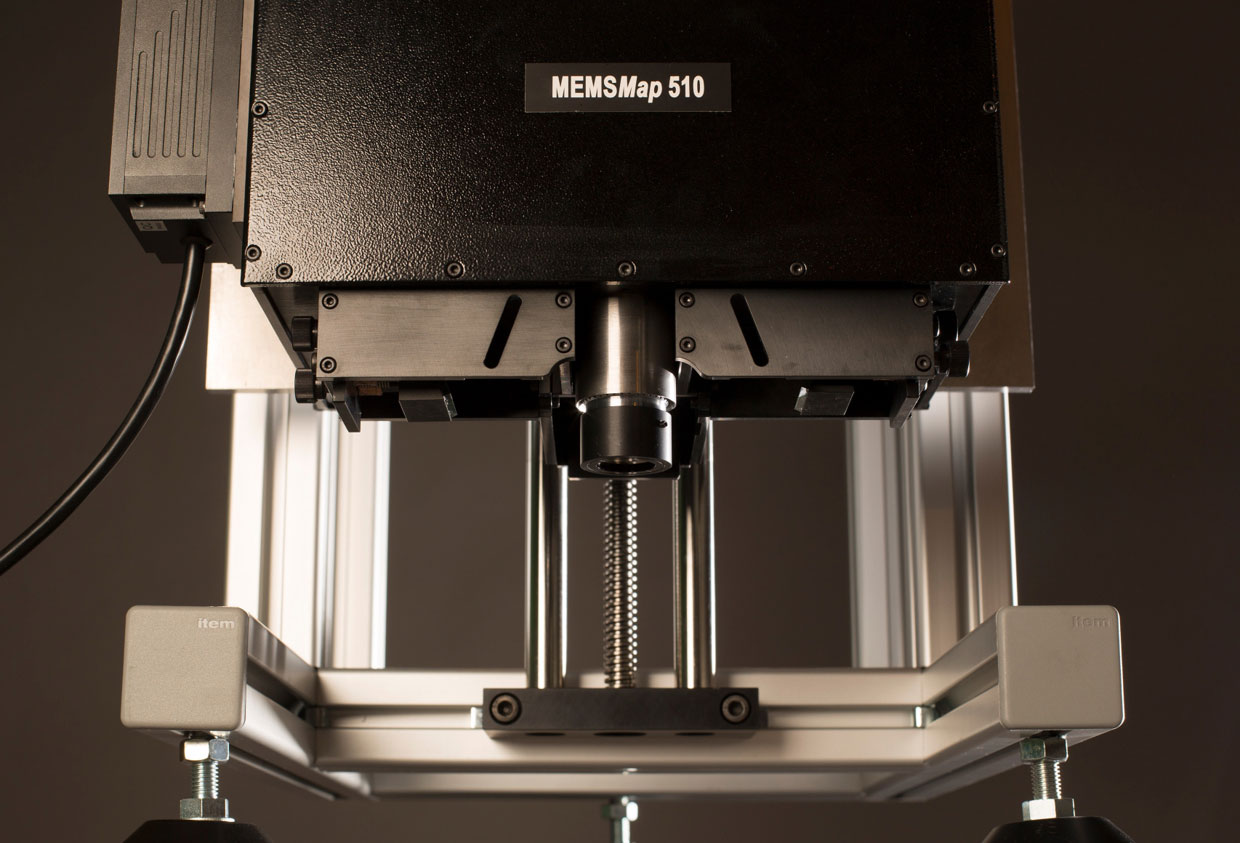

MEMSMap

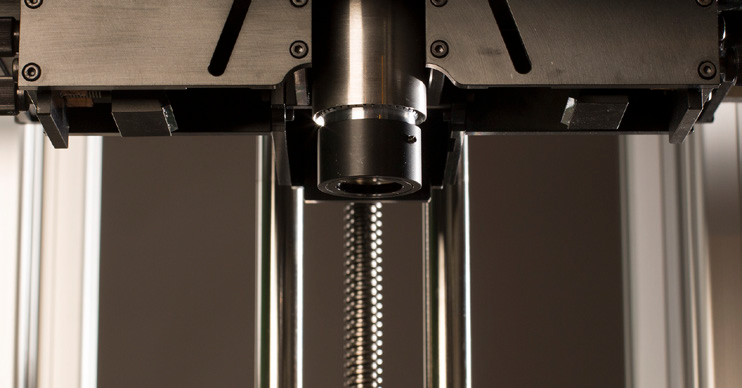

3D VIBROMETER SYSTEM

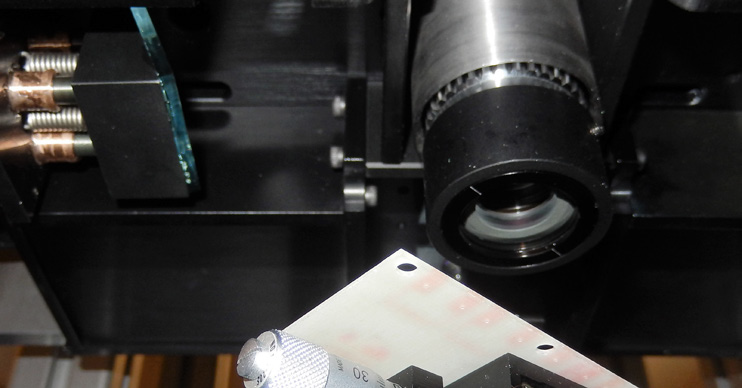

Laser based system for three dimensional measurements of high frequency, low amplitude vibrations of micro- structures. The MEMSMap can also measure static displacements and it can measure both rough and smooth surfaces with micrometer spatial resolution. By using long focal length objectives, the MEMSMap can perform measurements through windows and heat filters, via mirrors, as well as through liquid media.

APPLICATIONS

- MEMS and NEMS

- Microstructures

- Transducers

- Vibration mode analysis

- Response spectra

- Pressure sensors

- Accelerometers

- Gyroscopes

- Collision sensors

- High temperature measurements

- Vacuum chamber measurements

- Thermal deflection measurements

- Aging effect analysis

CLIENTS

- Automotive industry

- Sensor industry

- Medical industry

- Aerospace industry

- Electronic industry

- R&D

- Product testing

MULTIFUNCTIONAL SYSTEM FOR R&D AND TESTING OF MICROSTRUCTURES

The MEMSMap illuminates the target area with an expanded laser beam, while the object is imaged by a microscopic objective onto a CMOS sensor array. For out-of-plane measurements, an internal reference beam is used to interfere with the object light. For in-plane-measurements, two laser beams are used for object illumination.

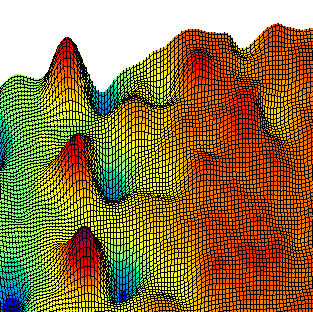

For vibration measurements the system computer uses a signal generator to drive an excitation device, and the target object is excited over a frequency range. Vibration amplitude fringes can be displayed in real-time, while a unique recording algorithm is used to calculate numerical amplitude and phase maps. For static deflection measurements the Optonor technology is based on phase shifting to record and calculate static deflections of the object under investigation.

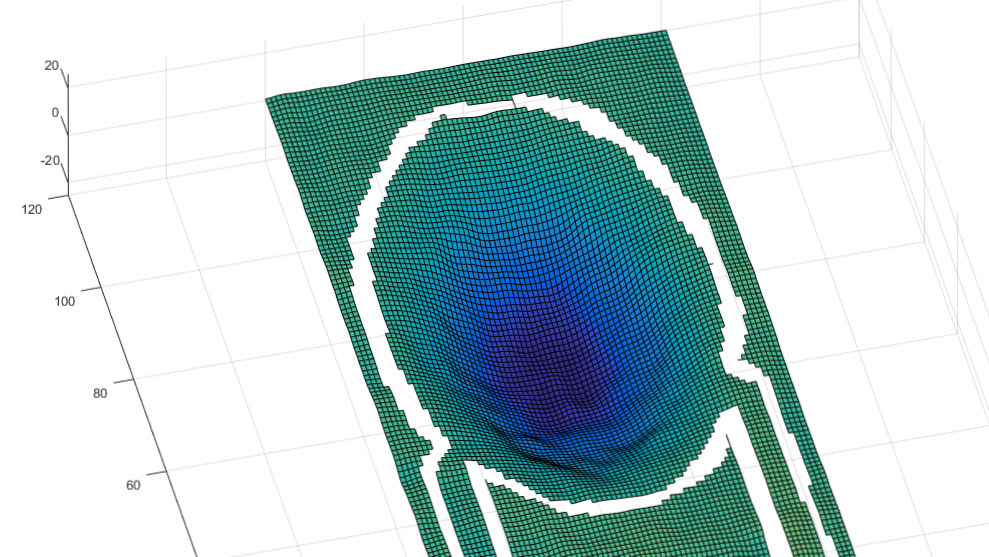

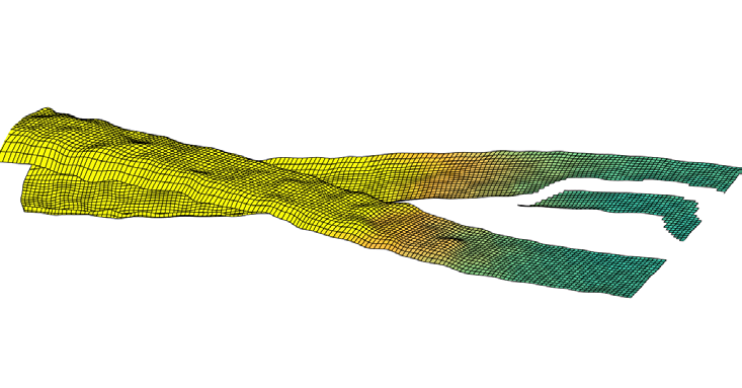

NUMERICAL RECORDINGS

The numerical mode of operation provides numerical measurements, in 3D, of amplitude, phase and static displacements. For vibration measurements, a full-field numerical recording with full HD resolution takes from a few seconds to a couple of minutes to perform. For static and quasi-static measurements, the numerical mode of operation finds the surface displacement between time t and time (t+Δt), where Δt can be from a few seconds to several minutes. This means that displacements can also be monitored and measured continuously over a period of time when the object is moved with a limited velocity during the recording period.

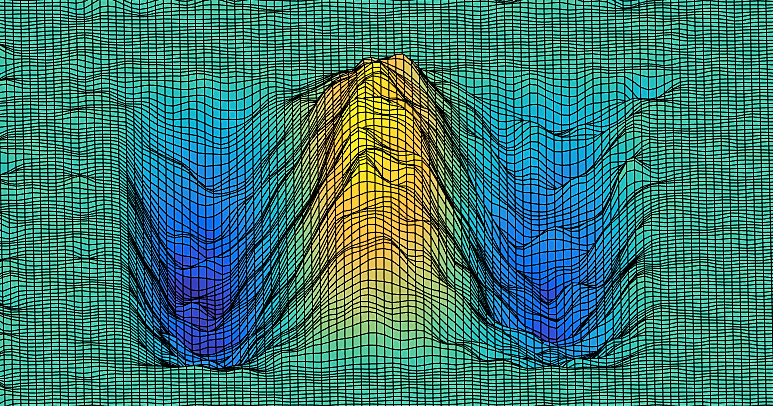

DYNAMIC MEASUREMENT

The MEMSMap measures the entire imaged area in real time, giving reliable, full-field data for both amplitude and phase of the vibrating object. No scanning of the area is required, and the acquisition of data is done at the same time for all points on the surface. Amplitude noise floor below 0.1 nanometers, and frequencies up to 240 MHz are standard for both in-plane vibrations and out-of-plane vibrations. The MEMSMap can be customized for even higher frequencies.

REAL-TIME ANALYSIS

The MEMSMap system provides two basic modes of operation for both static and dynamic measurements. In the real-time mode of operation, the full field measurements are updated 30-100 times per second, and the displacement map is presented in a quantitative way as iso-displacement contours. Any change in displacement that is a response to changes in excitation frequency, boundary conditions or applied loading is immediately seen on the monitor.

STATIC DEFLECTION MEASUREMENT

The MEMSMap measures and displays full field deflection maps with a displacement resolution of approximately 1-5 nanometers, depending on the required spatial resolution. Maximum static displacement range is several micrometers.

USER FRIENDLY OPERATION

The MemsMap system is a turn-key instrument with which the operator or technician can physically “see” the measurement result in real-time. In addition, the operator can make detailed numerical recordings for future documentation and analysis. There is no need for time consuming preparations or adjustments. The patented technology gives the user very high confidence in the measurement quality and output validity.

RELIABLE OUTPUT

The combination of the two modes of operation provides unique reliability and confidence in the validity of the measurement data. This is especially true when unexpected results arise, as the two different modes can pinpoint unusual defects and/or measurement issues.

SURFACE PROFILING

As an option, the MEMSMap can be used for surface profiling. This is done by using an optical mirror as the reference object, so that the surface of the test object is compared to the flat surface of the mirror. The surface profiling option is applicable to smooth and continuous surfaces.

ROBUST TECHNOLOGY

The underlying algorithms and filtering techniques have been improved over time to produce a very robust measurement system. The high sensitivity, accuracy and repeatability are achieved without costly anti-vibration installations. This system can be used in most standard laboratory environments for QA/QC or R&D applications.

FEATURES & BENEFITS

- Noncontact laser based instrument:

- Vibrations

- Static deflections

- Surface profiling

- 3D measurement: out-of-plane and in-plane measurements

- High frequencies: up to 240 MHz as standard, higher as an option

- High resolution displacement measurement

- Applicable to both rough and smooth surfaces

- Full-field measurements

- Two modes of operation both for vibration analysis and static deflection analysis

- Robust and user-friendly hardware and software