High frequency 3D Measurements of Microstructures

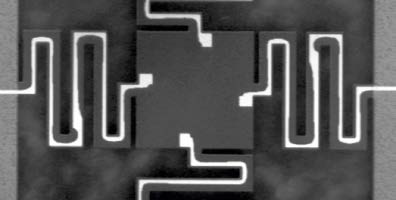

Modeling and designing micromechanical structures and MicroElectroMechanical Systems (MEMS) is challenging because of the sensitivity to material properties and boundary conditions.

“The Optonor solution allows the assessment of more sophisticated devices working at higher frequencies”

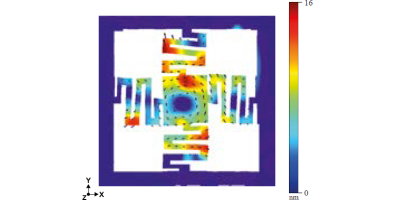

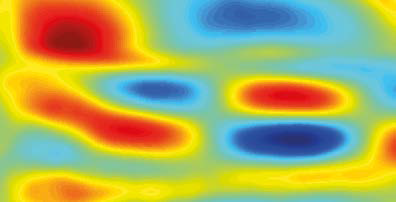

Having full-field, 3D information about vibration modes of both well-functioning and faulty samples is an important step in the development of such structures. The Optonor Microstructure Scale Vibrometer represents a powerful tool that can be used in research, development, manufacturing and product testing.

The technology provides solutions for verification of 3D modal shapes, quality factors and resonant frequencies, as well as static deflections and displacements. Measured data and results are presented in standard export formats for research and engineering.

FEATURES AND BENEFITS

- 2D in-plane mapping

- 3D in-plane and out-of-plane true mapping including full 3D phase acquisition

- Wide 3D frequency range: 0-240 MHz

- Amplitude resolution of 0.1 nm

- Static Deflection Analysis

- Full field real-time and numerical recordings

- Rough and smooth surfaces

- Animated displays and data-export solutions

- User friendly and robust

- Non-contacting laser based interferometric technology

- Object analysis in gaseous media such as air, as well as liquid media

APPLICATIONS

- Research and Development

- Quality and production control

- MEMS, NEMS and microstructures

- Transducers

PRODUCTS & SYSTEMS

- MEMS Map 510

- Measurement and Analysis Services