Non-Destructive Testing

Modern composite materials are light and strong. By choosing an appropriate combination of matrix and reinforcement materials, a new material can be made to meet the requirements of a particular application.

“The Optonor system has been used for testing of delaminations in jet-engine honeycomb components. It has performed excellent for many years!”

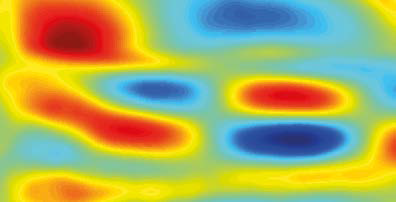

Failure mechanisms in composites are different from other materials and the inspection technologies available during development, production and in-service are limited. The defect detection technology presented by Optonor provides inspection and measurement solutions specially adapted to the failure mechanisms and mechanical characterization of composites. Measured data and results are presented in standard export formats for reporting and data storage.

FEATURES AND BENEFITS

- Fast, accurate and efficient

- User friendly and robust

- Testing of large and small structures

- Advanced filtering for testing in demanding environments

- Non-contact, laser based,

interferometric technology - Object excitation by piezo transducers

- Thermal and vacuum based excitation optional

- Clear and simple documentation

- Defect detection mapping

- Static deflection analysis

- Vibration Analysis

- Full-field measurement using either real-time or numerical analysis

APPLICATIONS

- Quality Control

- Product Testing and qualification

- Condition Monitoring

- Non Destructive Testing:

- Delamination

- Lack of bonding

- Impact damages

- Matrix and fiber cracking

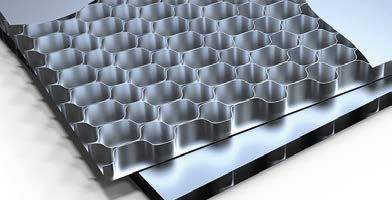

MATERIALS

- Fibre reinforced plastics

- Ceramic and metallic composites

- Sandwich structures

- Wood

PRODUCTS & SYSTEMS

- VibroMap

- ShearMap (coming soon)

- Measurement and analysis services